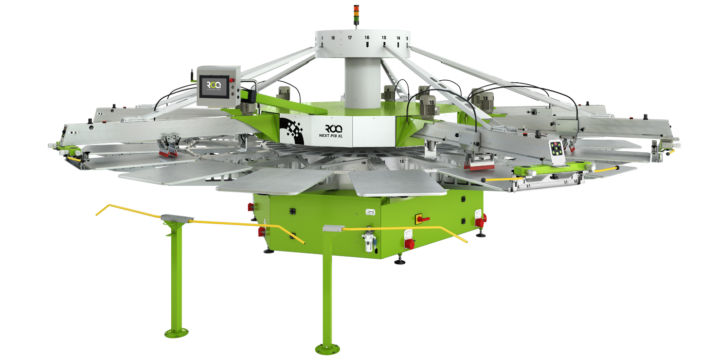

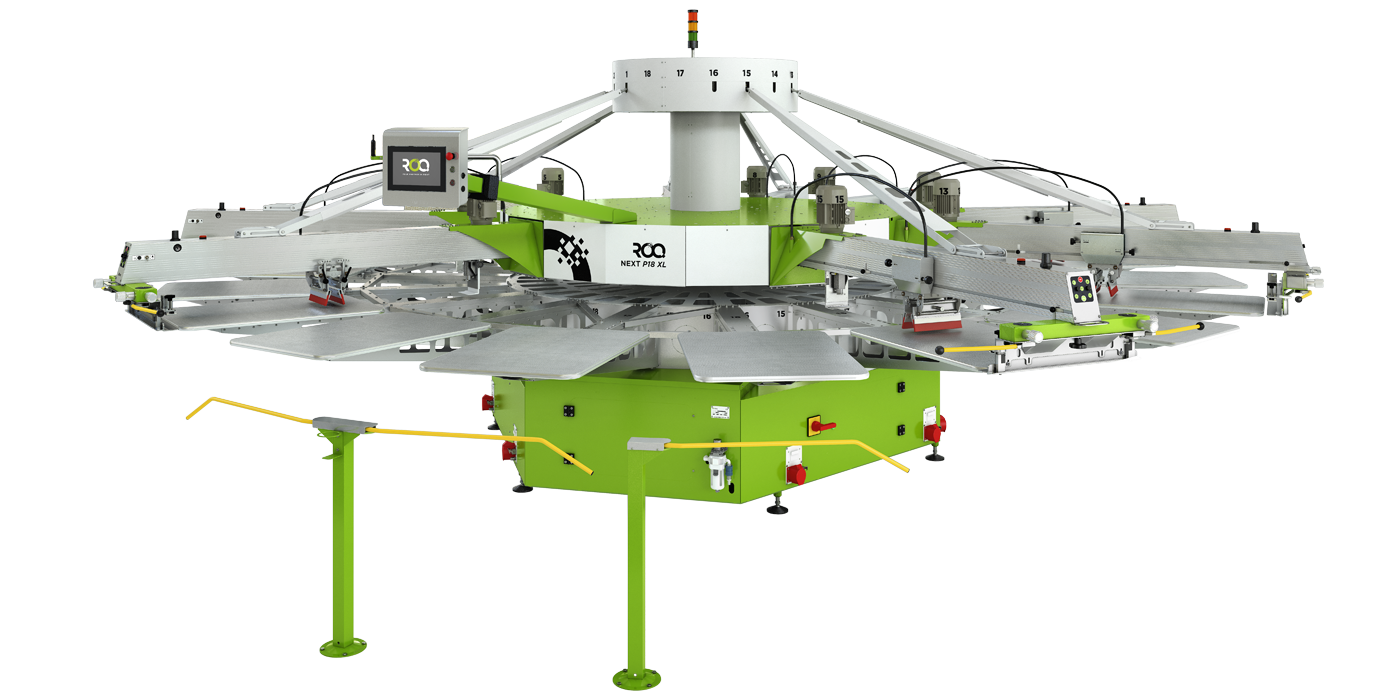

TECHNICAL SPECS

- Aluminum honeycomb pallet

- Squeegees movement with AC frequency drive

- Independent control panel on all printheads

- Choice of pneumatic screen holder: ”U” clamp or pin system

- Printheads independent elevation

- AC motor with high resolution enoder controlled by frequency drive for index system

- Printheads with high-lift position for quick and easy screen cleaning

- Central control panel with touch screen (10”)

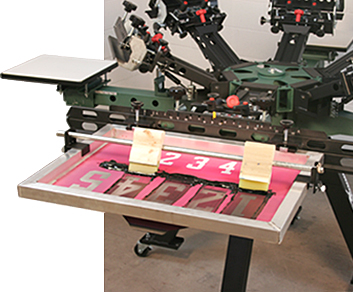

- Micro registration screen system with vernier scale

- Individual controls for managing print and flood speed, height and angle of the squeegee, and stroke length

- Placement of the flash cure units under the printhead

- Double index printing mode

Description

Do you need a machine with a high printing speed without ever losing quality? ROQ Next meets these requirements!

ROQ Next is equipped with high-quality components and uses the latest technological innovations. Independent control is possible on each print head for normal functions such as print speed and coverage, height and angle of the rulers as well as the stroke.