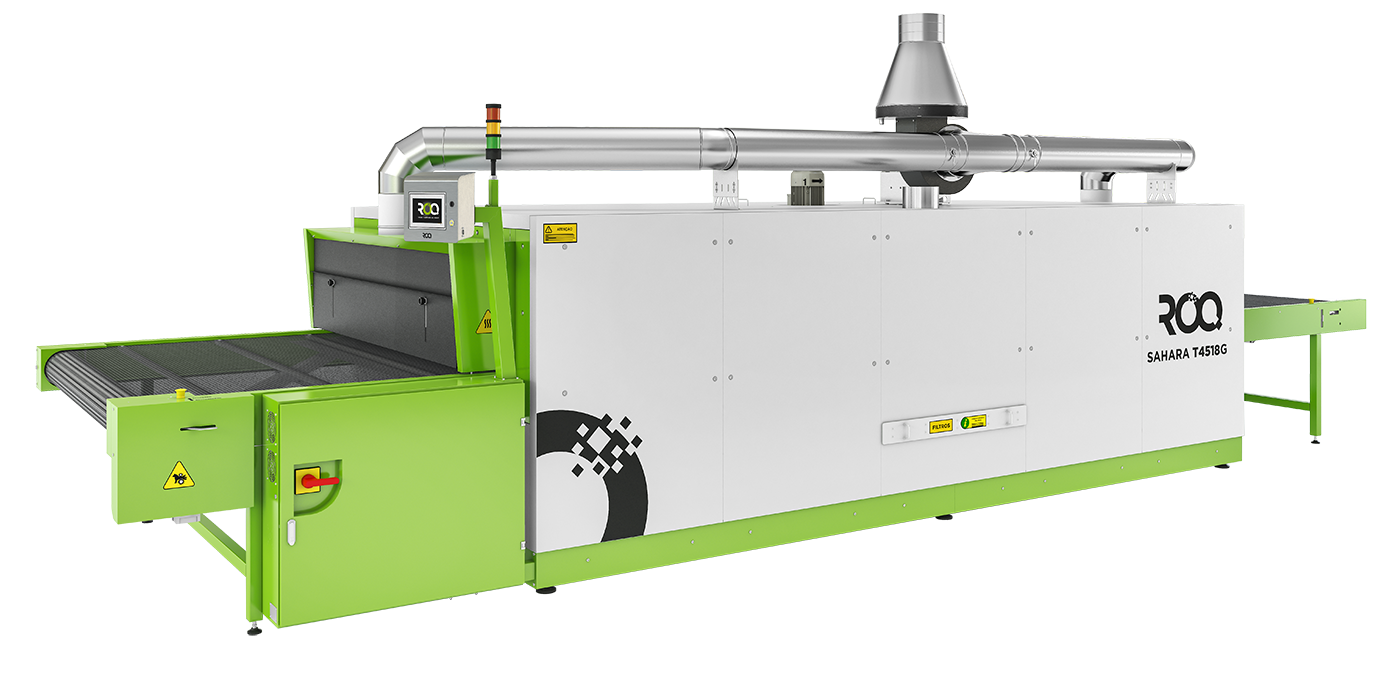

The ROQ SAHARA – It’s like having a desert at your service

TECHNICAL SPECS

- •Improved energy efficiency and thermal stability through its reinforced insulation

- Standby Mode that allows you to keep your dryer’s temperature during breaks at a reduced cost, further improving its energy efficiency

- Increased chamber entry height of 140 mm (5,5’)

- Improved noise reduction

- Axial flow fan for a constant hot-air circulation

- Air purification filter for the burner

- Antistatic and resistant mesh conveyor high tensile strength PTFE coated belt

- Faster and easier maintenance due to an improved filter access

- Updated user-friendly software with a brand-new recipe saving system to manage exposure time and overall temperature

- Digital temperature display

- Internal exhaustion header system per module

- Contact temperature control

- Min temp 90°C – Max temp 200°C

- Option of 2 conveyors with independent speed and direction (optional)

- Different length’s entry/exit openings (optional)

- ROQ SAHARA powered by gas with heat exchanger system (optional)

- ROQ SAHARA powered by gas, Electricity, or Both (optional)

Description

The ROQ SAHARA is a very versatile piece of equipment, able to adapt to any printing shop regardless of the conditions or type of energy source available. It can run on gas, electricity or both (MIX version), switching between them with the simple press of a button.

This oven has high energy efficiency and thermal stability, thus bringing added value to your business.