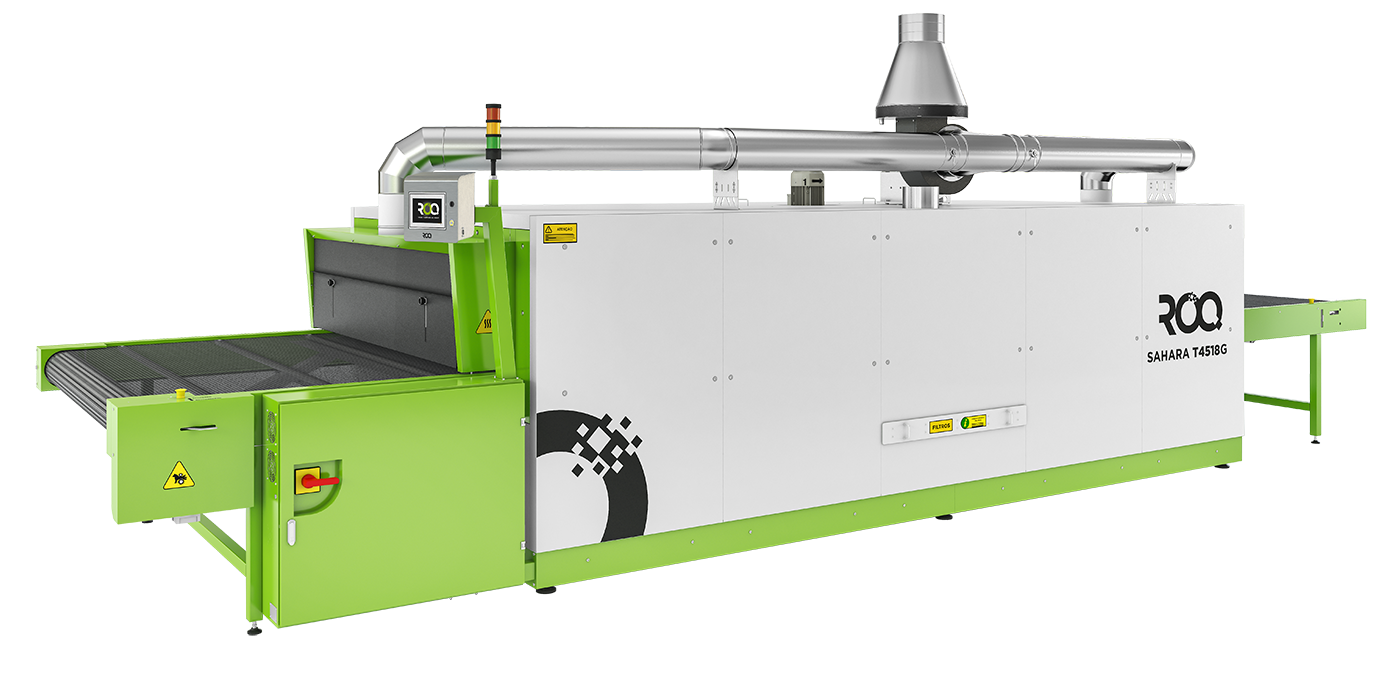

New BigRed™ 4D-54 Dryer Cures All Inks at Ultra-High Rates

A new BigRed™ 4D-54 conveyor dryer from Vastex features a pre-heating zone and high-efficiency air flow mapping, achieving ultra-high rates and side-to-side curing uniformity, while cooling the chamber skin, reducing noise and preventing dust contamination, it was announced by Mark Vasilantone, president.

Seven inches (17.8 cm) narrower than its predecessor, the compact dryer is equipped with a 54 in. (137 cm) wide conveyor belt, dual heating zones and four infrared heaters capable of curing up to 950 plastisol printed garments/h, 432 water-based or discharge-printed garments/h, and 144 garments/h printed with digital white ink.

A high-powered pre-heating zone surges ink temperatures past 300°F (149°C) within the first several inches of conveyor travel, maximizing dwell time at optimum curing temperatures and, in turn, conveyor belt speeds and dryer output.

Air intake fans located below the roof of the enclosure quietly draw ‘make-up’ air into the

chamber’s double-walled shell through filtered inlets along opposite exterior sides at rates up to 560 cfm (15.6 m3/min), serving to cool the outer shell for safety, while preheating the incoming air.

An exhaust fan located below the center of the conveyor belt draws the preheated air downward at rates up to 860 cfm (24 m3/min), over the garment and through the belt, removing heat, moisture and contaminants from the chamber.

To accommodate each shop’s layout, the 6 inch (15.2 cm) diameter exhaust fan outlet rotates 360 degrees for connection to ductwork, and the control box can be located on the right (standard) or left side of the chamber.

Exhaust filters located on both sides of the conveyor prevent garment lint from entering the blower or exhaust stack. Cleaning all filters before or after each shift can be accomplished in one minute according to the company, safeguarding printed images, the equipment and the shop environment.

Exhaust flow sensors with warning lights alert operators to a clogged exhaust line, clogged filter or blower failure. Other safety features include a light tower to monitor dryer status, and a ‘cool down mode’ for powering down.

Dual digital PID temperature controls maintain accuracy to +/-1°F (+/-0.5°C).

The heaters of the new dryer carry a 15-year warranty, and feature closely spaced coils that provide high-density, medium-wavelength infrared heat for maximum cure speed without cold spots or under curing associated with conventional units.

The dryer’s capacity can be doubled, tripled or quadrupled when needs increase by adding one, two or three additional heating chambers and extending the conveyor belt. Vasilantone says a BigRed™ 4D-30 version with 30 inch (76 cm) wide conveyor belt will soon follow.