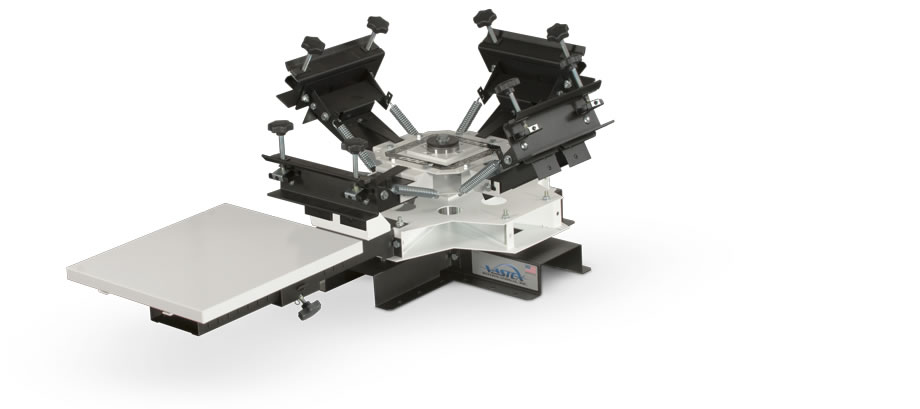

Light-Duty Tabletop Garment Printer

All-new V-100 tabletop screen printing presses are engineered specifically for 1- to 4-color garment printing, overflow printing, and printing in restricted spaces such as spare rooms and mobile shops — at low costs generally associated with machines of lesser accuracy and durability.

Quality results are achieved by retaining critical components from Vastex’s commercial and industrial models: no-warp steel pallets, screen off-contact and level adjustments, rotor detent for positive engagement of pallets, and three-point bearing locks providing pinpoint registration of print-heads-to-pallets and allowing all-heads-down printing.

The V-100-11 1-station, 1-color base model is expandable, allowing the addition of individual pallet stations and print heads as needs grow.

The V-100-44 model is configured as new with four pallet stations and four print heads.

Units with multiple stations and colors allow all-heads-down printing using screens up to 21 in. (51 cm) wide, maximizing productivity when printing registered spot colors and process colors, or multiple one- and two-color jobs simultaneously.

Compared with commercial and industrial presses from Vastex, V-100 presses are characterized by lighter-duty construction, tabletop-only configuration, omission of quick registration micros, increased use of fasteners versus welds, and shipping of units disassembled in multiple cartons.

Approximate assembly time is two to four hours.

Options include neck guides and rubber tops for the included pallets, and a variety of specialized pallets for long sleeves, pant legs, caps, umbrellas, koozies and other textiles and hard goods.