RhinoClean Dip Tanks

The RhinoClean Dip/Soak Tanks Systems are designed for fast, safe and efficient removal of screen printing stencils. The RhinoClean System, used in conjunction with RhinoClean ER 8500L emulsion Remover or AP1000 (all in one) Ink Degradent Emulsion Remover, will effectively remove all types of emulsion from the screen frame. It’s easy; once the emulsion is soft simply remove with high pressure washer.

Using a RhinoClean Dip Tank/Emulsion Removal System helps reduce chemical waste. It also allows the operator to clean another screen while the next one is soaking. Thus, it saves time and money. The system helps meet compliance by minimizing the volume of chemicals going down the drain therefore you will lessen the carbon foot print on our environment. Our dip tanks users reduce chemical consumption by up to 70%, decreasing labor needs by up to 50%. The average savings is $.50 per screen!

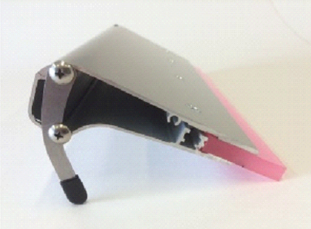

Features of the RhinoClean Dip/Soak Tanks:

- Polyethylene Construction

- One piece molded construction

- Ideal for use with 2 in 1 ink and emulsion removers

- Drain Spigot

- Multi Screen Units

- Top Loading Design

- Hold Down Lid

- Tank support band on specific models

Models:

- AP2024 / 26” x 8” x 26” (20 gal. Capacity) Holds 4 Screens 1.5″ Profile

- AP2331 / 33” x 14” x 24” (55 gal. Capacity) Holds 8 Screens 1.5″ Profile

- AP2536 / 40” x 16” x 38” (100 gal. Capacity) Holds 9 Screens 1.5″ Profile

Benefits of the RHINOCLEAN System: free up employee time to spend on other tasks instead of screen cleaning; extends the life of the ink degradant/emulsion remover and reduces employee exposure to chemicals.