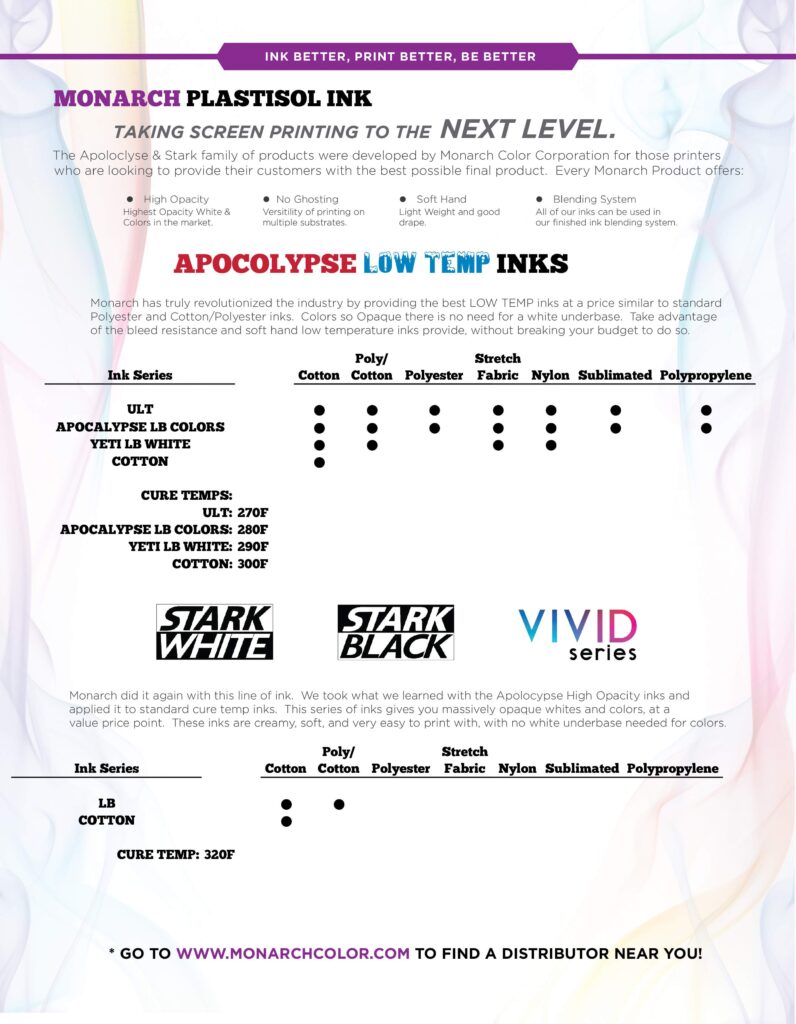

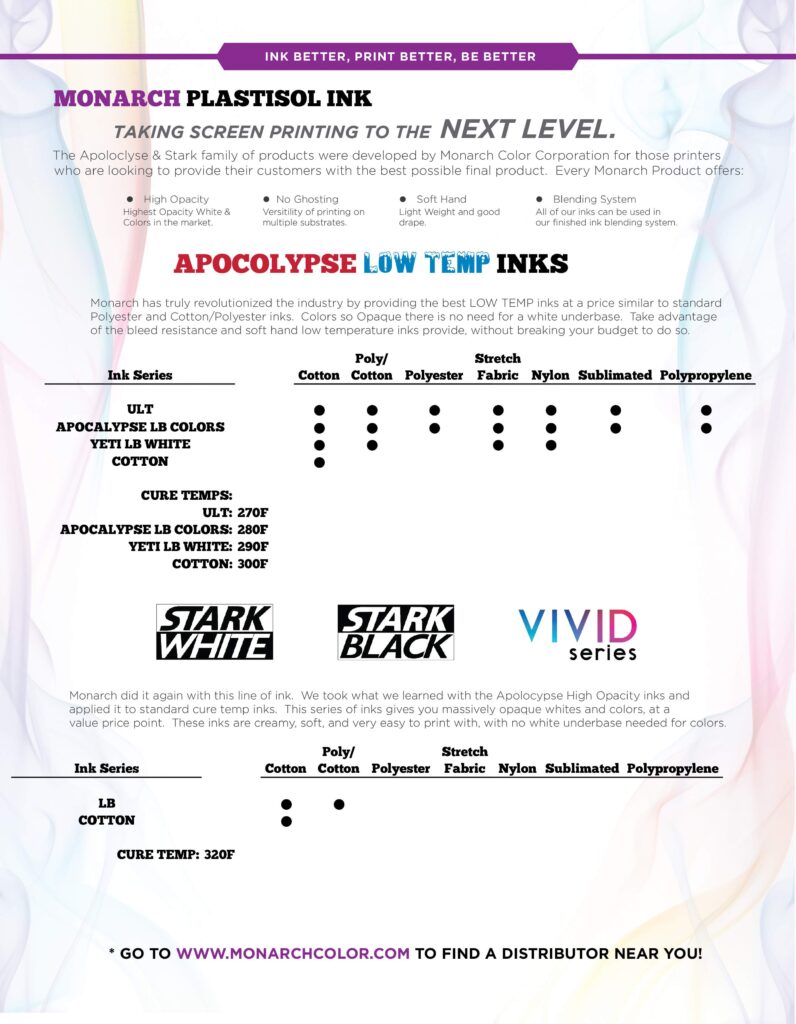

Monarch did it again with this line of ink. We took what we learned with the Apocalypse High Opacity inks and applied it to standard cure temp inks. This series of inks give you massively opaque white and colors, at a value price point. These inks are creamy, soft, and very easy to print with, with no white underbase needed for colors.

These inks are non-phthalate and lead-free plastisol screen printing inks for screen-printing cotton, cotton/poly blends, and tri-blends. Our inks are no-odor inks and meet environmental requirements for printing onto textiles.

All series pass all requirements of CPSC, HR-4040, CA PROP65, & CPSIA.

When Monarch entered the Garmet printing market, our goal was to create the newest, most innovative plastisol screen printing inks that surpassed the current ink standards for; color, opacity, workability, performance, and bleed resistance. While leaving a matte finish, soft hand, and excellent drape that all customers want.

Our Stark White or Black comes in both Low Bleed and Cotton. They are light weight, high opacity, inks for printing onto Polyester Blends, Cotton Blends, and 100% Cotton. The Stark White is designed to have less fibrillation compared to other whites on the market. These inks will cure at 320°F and have a soft hand, satin finish, and good bleed resistance.

Ink Characteristics:

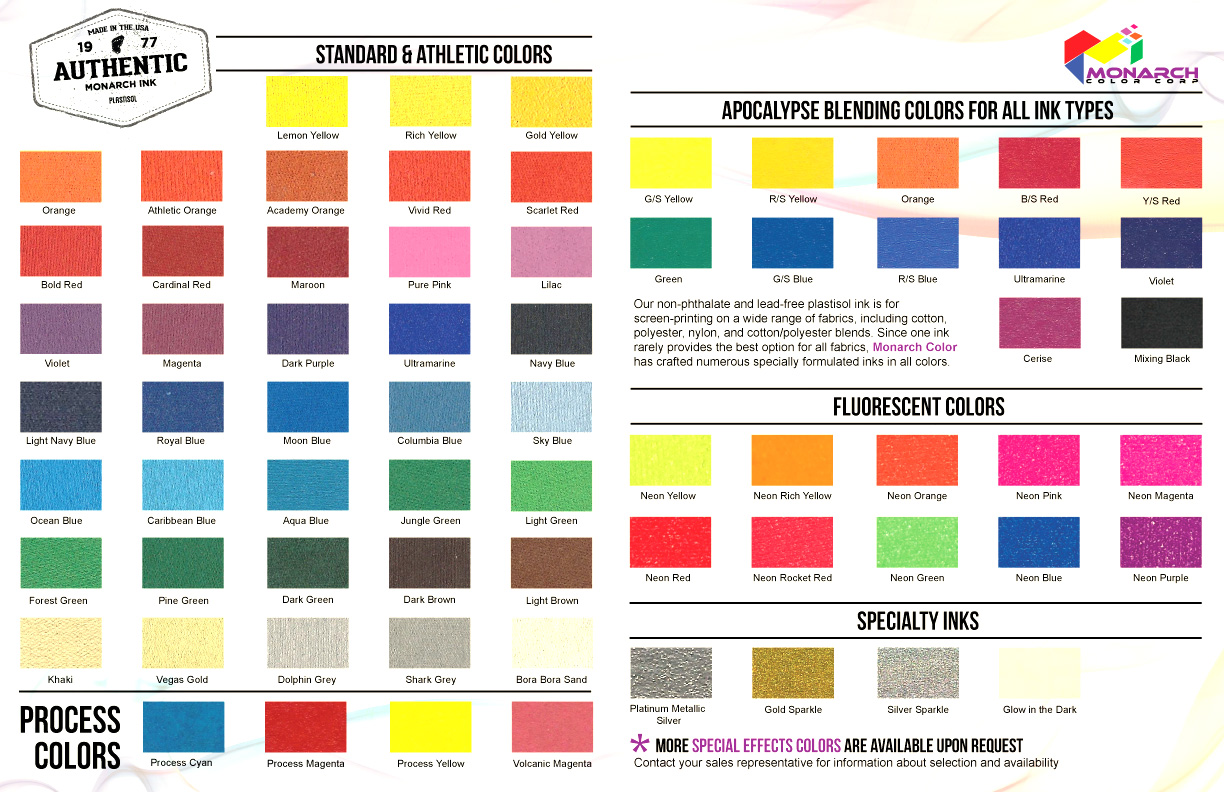

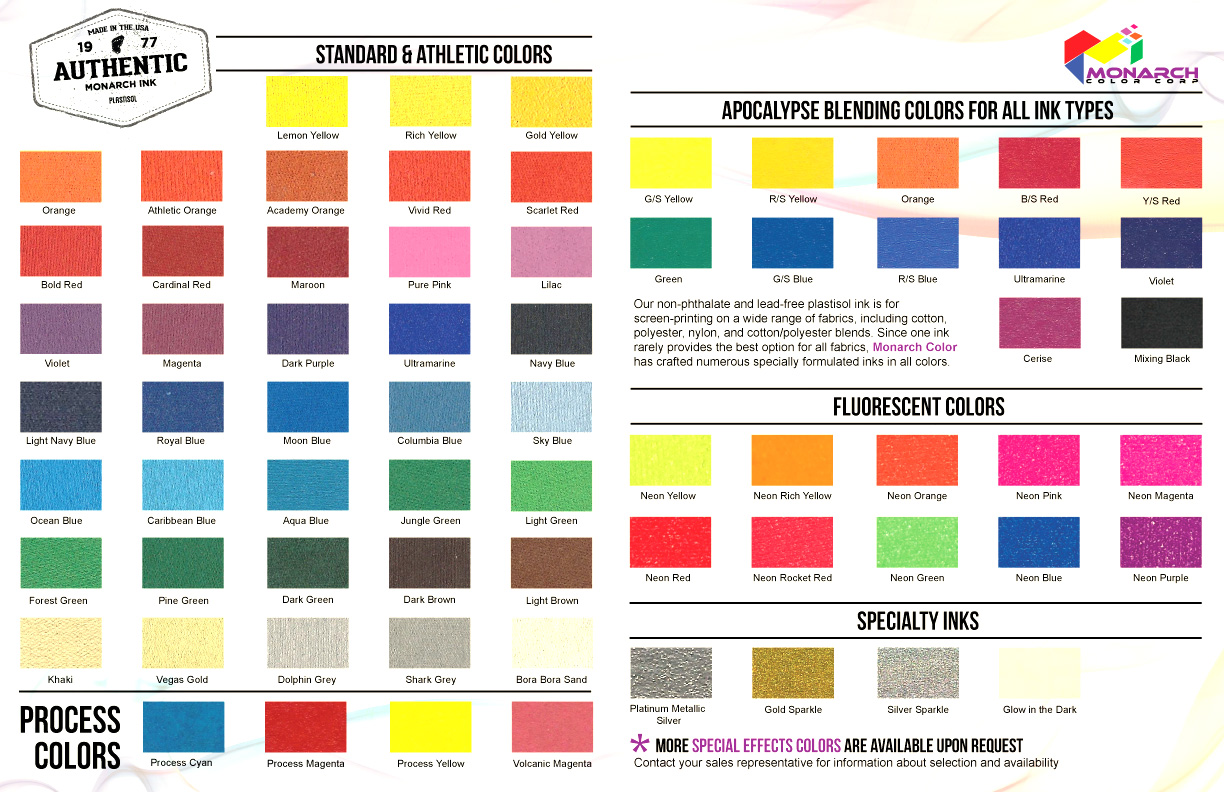

Monarch’s non-phthalate and lead-free plastisol screen printing ink is a textile ink for screen-printing cotton, cotton/poly blends, tri-blends, polyester, and nylon. Since one ink rarely provides the best performance for all fabrics, Monarch has crafted numerous specially formulated inks that will keep you one step ahead of the rest of the screen-printing industry. Our Non-Phthalate, lead free plastisols are no-odor inks and meet environmental requirements for printing onto textiles.

All series pass all requirements of CPSC, HR-4040, CA PROP65, & CPSIA.

Monarch’s Apocalypse Blending System Our Apocalypse Blending system is a state of the art, high opacity, color mixing system available in:

Unlike other inks, all of our plastisol colors, whether you are using Low Temp or Standard cure temp inks, use the same blending formulas. It will enable you to accurately create most PMS colors, no matter which of our inks you are using.

XOLB, “Xtra Opaque, Low Bleed” Inks are high opacity multi-purpose inks that are designed to produce extremely opaque prints, yet are very easy to print on a manual press. The smooth, creamy consistency leaves an even uniform print on white flash bases and can be opaque on black without a white base with screens as fine as 160 TPI (62 TPcm) mesh. XOLB inks are fast flashing, cure with a non-tack surface, and contain clean bright pigments. The fast flash speed allows for shorter dwell times and faster production output. CAUTION: When printing on any polyester blended garments, always test prior to production for any potential bleed/dye sublimation problems. If you are unsure of the quality or stability of the garment you are decorating, lay down a low bleed white base using our XOLB-158, XOLB-159, or XOLB-151.

XOLB inks print well through screen meshes in the range of 83-305 TPI (32-120 TPcm). Screens stretched to a minimum of 25 newtons are recommended. If using lower tension screens, adjust off contact accordingly. Use just enough squeegee pressure to deposit the ink on the surface of the shirt. This will enhance the opacity and also ensure a better cure. Try not to drive the ink into the fabric. A 70 durometer sharp squeegee is recommended.

Use any direct emulsion or capillary film.

Parameters vary between all flash units. Flash for 2-3 seconds with the ink deposit reaching 150-250°F (65-121°C). Ink should be dry and without tack. Warning: Over flashing can cure the ink and prevent adhesion between coats of ink.

Cure at 325°F (162°C) over a 60-90 second period, depending on oven type and thickness of ink deposit. A thicker deposit will take longer to cure as the heat must penetrate through the entire ink layer.

Use any of the commercially available products for the cleanup of plastisol inks.

QCM Plastisol Ink contains no leaded pigments and, when properly disposed of, has no environmental impact. Use a screen wash for plastisols for cleanup. Scrape screens carefully and store ink for reuse. Minimize unusable scrap ink by segregating ink by color. QCM PPR-901 Black pigment can be used to convert old ink into black ink for waste elimination.

PRODUCT OVERVIEW:

MTL “Precious Metal” Inks are bright, opaque, metallic plastisol screen printing inks. Add pop to your design as either an accent or as a color replacement to jazz up an old design.

PRINTING:

MTL inks print well through screen meshes in the range of 83-110 TPI (32-120 TPcm) Screens stretched to a minimum of 25 newtons are recommended. If using lower tension screens, adjust off contact accordingly. Use just enough squeegee pressure to deposit the ink on the surface of the shirt. This will enhance the opacity and also ensure a better cure. Try not to drive the ink into the fabric. Squeegee durometers of 60 or 70 and are recommended.

STENCIL:

Use any direct emulsion or capillary film.

SUBSTRATES:

MTL inks may be printed on 100% cotton, cotton blends, acrylics and polyesters or poly/cotton blends. Pre-production run testing is always recommended to check for adhesion, washability, dye migration problems, amongst other things.

MODIFIERS:

MTL inks are ready to use. They can be extended using LFP-1002 base, but opacity will be affected. For printing on Nylon shell material waterproofed, use MF-66 Nylon Bonding Agent.

CURING:

Cure at 325°F (162°C) over a 60-90 second period, depending on oven type and thickness of ink deposit. A thicker deposit will take longer to cure as the heat must penetrate through the entire ink layer.

CLEANUP:

Use any of the commercially available products for the cleanup of plastisol inks.

ENVIRONMENTALLY FRIENDLY:

QCM Plastisol Ink contains no leaded pigments and, when properly disposed of, has no environmental impact. Use a screen wash for plastisols for cleanup. Scrape screens carefully and store ink for reuse. Minimize unusable scrap ink by segregating ink by color.

PRODUCT OVERVIEW:

Glitter Inks are made with QCMs high performance clear glitter base to result in easy printing and high brightness. The particle size allows for good printing through 40 TPI (15 TPcm) mesh screens. Each color is also available in powder for sprinkle or dry print applications.

PRINTING:

GL Inks can be printed through 25-40 TPI (9-15 TPcm) screens. Screens stretched to a minimum of 25 newtons are recommended. Use a 60-70 durometer squeegee. For best results 2-3 passes may be needed.

STENCIL:

Use any direct emulsion or capillary film.

SUBSTRATES:

GL Inks can be printed on all garments. Test for adhesion and bleed on poly and poly blends.

MODIFIERS:

Extend with LFP-1002 base and/or P-5011 curable reducer.

CURING:

Cure at 325-350°F (162-176°C) for approximately 60-90 seconds. This is a thick ink deposit. Check for proper cure before production.

CLEANUP:

Use any of the commercially available products for the cleanup of plastisol inks.

ENVIRONMENTALLY FRIENDLY:

QCM Plastisol Ink contains no leaded pigments and, when properly disposed of, has no environmental impact. Use a screen wash for plastisols for cleanup. Scrape screens carefully and store ink for reuse. Minimize unusable scrap ink by segregating ink by color.

PRODUCT OVERVIEW:

Being both fluorescent and semi-opaque, AP Semi-Opaque Fluorescent inks produce beautiful, even, bright prints. While opaque enough to be printed without the need of an underbase on light and medium grain garments, it is still recommended to print an underbase white on dark colored fabrics.

PRINTING:

AP Semi-Opaque Fluorescent inks print well through screen meshes in the range of 83-160 TPI (32-62 TPcm). Higher mesh counts may be used with a small loss in opacity. Screens stretched to a minimum of 25 newtons are recommended. If using lower tension screens, adjust off contact accordingly. Use just enough squeegee pressure to deposit the ink on the surface of the shirt. This will enhance the opacity and also ensure a better cure. Try not to drive the ink into the fabric. A 60/90/60 or 70 durometer sharp squeegee is recommended.

STENCIL:

Use any direct emulsion or capillary film. Additives: N/A.

CURING:

Cure at 325°F (162°C) over a 60-90 second period, depending on oven type and thickness of ink deposit. A thicker deposit will take longer to cure as the heat must penetrate through the entire ink layer.

CLEANUP:

Use any of the commercially available products for the cleanup of plastisol inks.

ENVIRONMENTALLY FRIENDLY:

QCM Plastisol Ink contains no leaded pigments, and, when properly disposed of, has no environmental impact. Use a screen wash for plastisols for cleanup. Scrape screens carefully and store ink for reuse. Minimize unusable scrap ink by segregating ink by color. QCM PPR-901 Black pigment can be used to convert old ink into black ink for waste elimination.